The post S5 Attritor with Polyurethane Coating Addresses Semiconductor and Photonics Material Needs first appeared on Union Process.

]]>

Union Process sales manager, Brian Li, said, “The customer will be using ceramic zirconium oxide yttria grinding media for this metal-free wet milling application, which ensures optimal particle size reduction, uniform dispersion, and high grinding efficiency. This approach will also aid in minimizing contamination in the final product.”

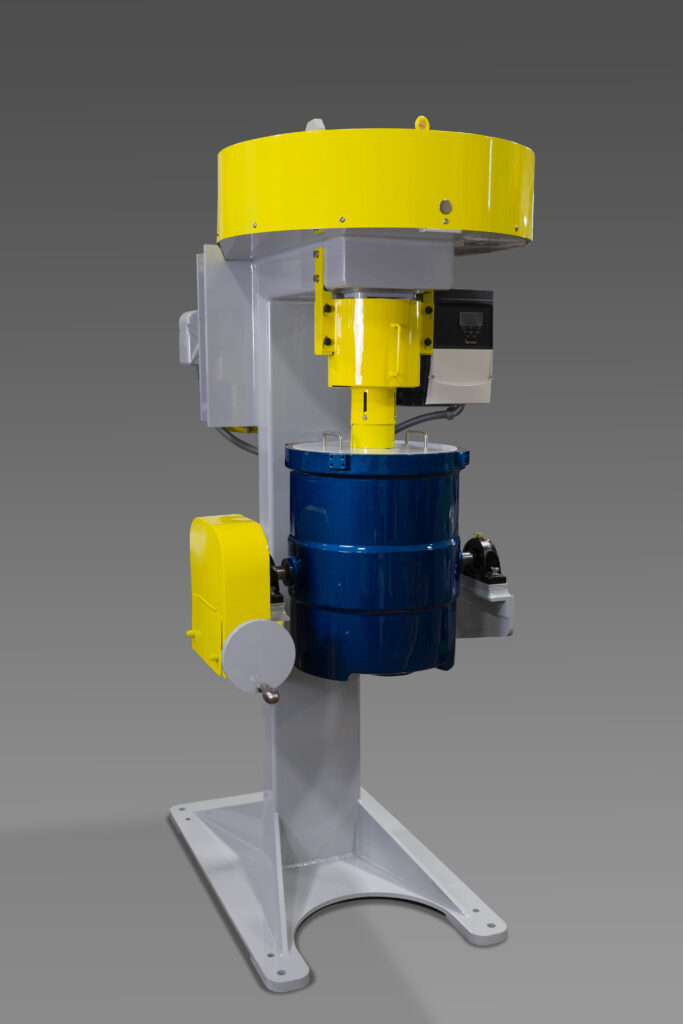

The Attritor is powered by a 10 HP, totally enclosed fan cooled (TEFC), inverter duty motor. The 460V/3PH/60Hz variable frequency drive has a NEMA 4X controller enclosure and the LCD Human Interface Module (HIM) is programmed to display agitator RPM and motor HP.

The grinding tank is stainless-steel, polyurethane-coated, and jacketed for temperature control. The agitator assembly is comprised of a plastic-sleeved stainless steel shaft with polyurethane coated steel reinforced agitator arms. The system is completed with a two-piece, plastic Ultra High Molecular Weight Polyethylene (UHMW) cover.

Union Process is a global manufacturer of particle size reduction and dispersing equipment, a supplier of grinding media and a provider of material characterization services for a broad range of research and industrial applications. Since 1946 the company has been developing and building custom Attritors. Union Process invented and developed Attritor technology and manufactures wet and dry grinding mills as well as horizontal bead mills. Attritor is a registered trademark of Union Process, Inc.

Contact us for more information.

Company Contact

Union Process, Inc.

Brian Li, Sales Manager

330.929.3333 x400

bli@unionprocess.com

The post S5 Attritor with Polyurethane Coating Addresses Semiconductor and Photonics Material Needs first appeared on Union Process.

]]>The post Corrosion-Resistant Attritor Introduces a High-Durability Milling Solution first appeared on Union Process.

]]>

Union Process sales manager, Chuck Major, says this mill “was specially constructed to withstand the corrosive nature of high pH slurries that the customer processes. The SL5 Attritor was the best choice because of its ability to efficiently reduce particle size and provide corrosion resistance. Additionally, the Attritor provides ease of use, better access to the milling chamber for formulation adjustments and quicker cleaning between batches.

The Attritor is powered by a 7.5 HP, totally enclosed fan cooled (TEFC), inverter duty motor. The 230V/3PH/60Hz variable frequency drive has a NEMA 4X 12 controller enclosure and the LCD Human Interface Module (HIM) is programmed to display agitator RPM and motor HP.

The grinding tank is stainless-steel and jacketed for cooling. The agitator shaft and arms are stainless steel with “L” arms. The system is completed with a two-piece, stainless steel cover with lockdown clamps.

Union Process is a global manufacturer of particle size reduction and dispersing equipment, a supplier of grinding media and a provider of material characterization services for a broad range of research and industrial applications. Since 1946 the company has been developing and building custom Attritors. Union Process invented and developed Attritor technology and manufactures wet and dry grinding mills as well as horizontal bead mills. Attritor is a registered trademark of Union Process, Inc.

Contact us for more information.

Company Contact

Union Process, Inc.

Brian Li, Sales Manager

330.929.3333 x400

bli@unionprocess.com

The post Corrosion-Resistant Attritor Introduces a High-Durability Milling Solution first appeared on Union Process.

]]>The post Customized SL5 Wet Grind Attritor Provides Efficient and High-Precision Metal Powder Milling Solution first appeared on Union Process.

]]>

Union Process sales manager Chuck Major highlighted the special approach of this Attritor which it is “not only able to reduce particle size but also creates a unique particle morphology.”

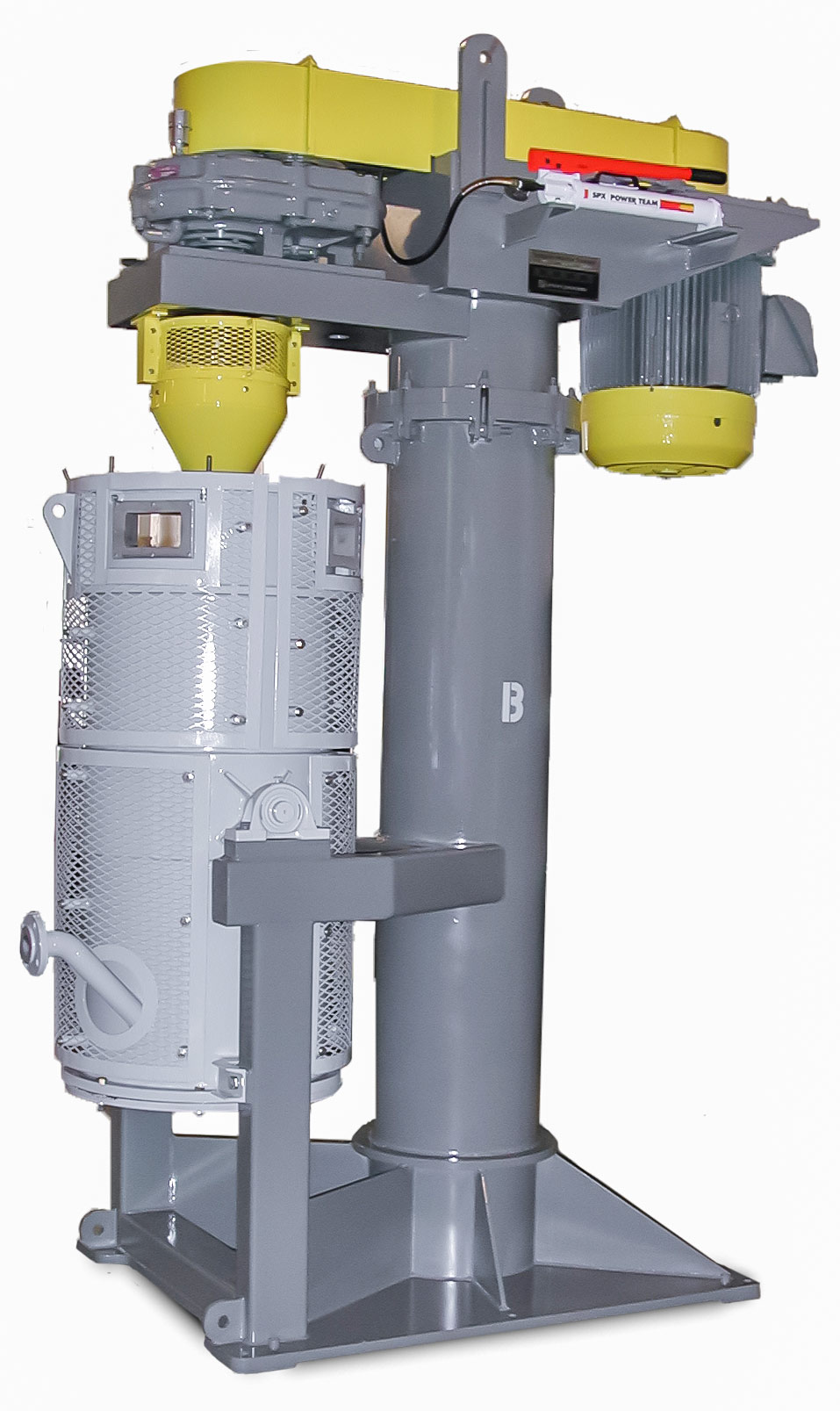

The Attritor is powered by a 10 HP, explosion-proof motor. The variable frequency drive is installed in a NEMA 12 enclosure, and the LCD Operator Interface Module (OIM) is programmed to display agitator RPM, motor amperage, and motor HP.

The Attritor is outfitted with a ten-gallon stainless-steel, jacketed grinding tank for temperature control. The stainless-steel agitator shaft is configured with 440C hardened stainless steel L-arms. The system includes a mechanical tachometer, explosion-proof operator station, and a one-piece cover with a special floating Teflon shaft seal to limit the solvent vapor loss.

Union Process is a global manufacturer of particle size reduction and dispersing equipment, a supplier of grinding media and a provider of material characterization services for a broad range of research and industrial applications. Since 1946 the company has been developing and building custom Attritors. Union Process invented and developed Attritor technology and manufactures wet and dry grinding mills as well as horizontal bead mills. Attritor is a registered trademark of Union Process, Inc.

Since 1946, Union Process has been developing and building custom Attritors from a wide variety of applications for customers all over the world

Contact us for more information.

Company Contact

Union Process, Inc.

Brian Li, Sales Manager

330.929.3333 x400

bli@unionprocess.com

The post Customized SL5 Wet Grind Attritor Provides Efficient and High-Precision Metal Powder Milling Solution first appeared on Union Process.

]]>The post Union Process Fills Niche with New Attritor first appeared on Union Process.

]]>The Q-03 features a 1-HP motor with a variable frequency drive, metal-free ceramic contact components, a ?” NPT air diaphragm pump assembly with ground dampening enclosure, and a 1-gallon premix tank with electric mixer. Both the grinding tank and premix tank are jacketed for cooling. The recirculation capabilities of the Q-03 provide a larger batch capacity relative to its size, a substantial cost savings on wear items and parts, and a more narrow particle distribution.

“The lab-scale Q-03 is an effective alternative to a wet batch process system,” said Chuck Major, Union Process Sales Manager. “We can work with any customer to configure a unit that will meet their specific needs.”

Since 1946, Union Process has been developing and building custom Attritors from a wide variety of applications for customers all over the world

Contact us for more information.

Company Contact

Union Process, Inc.

Brian Li

bli@unionprocess.com

330.929.3333

The post Union Process Fills Niche with New Attritor first appeared on Union Process.

]]>The post Major Confectionary Manufacturer Acquires Attritors from Union Process first appeared on Union Process.

]]>

Each of the four specialized grinding systems include a 450% starting inverter duty motor and an LCD screen that displays agitator RPM, motor AMPS, and horsepower being utilized at any given time.

“The precision grinding capabilities of the Q-Series are important for chocolate producers because chocolate must be ground down to 20 microns and under,” said Chuck Major, Union Process Sales Manager. “The Q-50 Attritors produce a fine, even particle dispersion that result in a very consistent end product.”

Chocolate sales spiked by as much as 13% during the COVID pandemic and are expected to reach $20 billion by 2025. Many different types of food processors have turned to Union Process to help keep pace with rising demand and to manage supply chain disruptions caused by the pandemic, labor shortages, and other factors.

Since 1946, Union Process has provided custom grinding and dispersion solutions for a wide variety of applications for customers all over the world.

Since 1946, Union Process has provided custom grinding and dispersion solutions for a wide variety of applications for customers all over the world.

Contact us for more information.

The post Major Confectionary Manufacturer Acquires Attritors from Union Process first appeared on Union Process.

]]>The post Union Process Lime Slaker is Used by the Agricultural Industry to Process Hydrated Lime first appeared on Union Process.

]]>

A company related to the agricultural industry recently acquired a custom CLS-60 Attritor from Union Process. The patented Stirred Vertical Ball Mill Lime Slaker is a continuous mill that processes quicklime into hydrated lime. Hydrated lime is used extensively in agriculture, construction, and other industries. UP CLS Attritors are unique in that they eliminate grit separation and disposal problems by slaking the lime as well as grinding the inert grit.

“The separation tank features primary and secondary chambers separated by a wall that allows the slurry to flow from the bottom of the first chamber to the second,” said Chuck Major, Union Process Sales Manager. “Coarse grit settles to the bottom of the first chamber and is pumped back into the mill for further grinding. The finer particles of hydrated lime flow upward into the second chamber and exit to the lime slurry storage tank.”

The CLS-60 has a 50-horsepower motor, a working media volume of 30 gallons and a maximum thruput of 8100 pounds per hour. The CLS Attritor’s relatively compact size allows it to easily fit under the skirt of the lime silo, making it unnecessary to have an additional building to house the mill. This means substantial savings in both space and cost.

Since 1946, Union Process has provided custom grinding and dispersion solutions for a wide variety of applications for customers all over the world.?

Contact us for more information.

The post Union Process Lime Slaker is Used by the Agricultural Industry to Process Hydrated Lime first appeared on Union Process.

]]>The post Union Process Engineered Products Play Key Role in Overcoming Supply Chain Interruptions first appeared on Union Process.

]]>

Akron, Ohio, June 10, 2021—Industries all over the world have experienced supply chain interruptions and raw material shortages resulting from COVID-19 shutdowns and other factors. These disruptions have provided insight into just how fragile manufacturing processes can be and the importance of keeping strict controls in place to help reduce or eliminate the loss of costly and scarce raw materials and other commodities.

For food processers, chemical suppliers, paint manufacturers and many others, Union Process has played a crucial role in managing and maintaining bulk materials and other resources. The Akron, Ohio-based firm manufactures Attritors, horizontal bead mills (DMQX-series) and other industrial grinding and size-reduction systems that serve as vital components in complex production and manufacturing networks.

Versatility is one reason industrial products manufactured by Union Process are used in so many different industries. Attritors can work in tandem with mixers as part of a milling system but are also available as stand-alone units. The mixing tanks can also be purchased separately. Union Process customers are able to specify the exact components needed for their very specific tasks.

Union Process mixing tanks are available in capacities from five to 1,000 gallons and can be configured many different ways specific to their intended use. Typically, a mixing tank is equipped with a disperser that can feature a variety of different impellers. Connected to a central shaft and powered by a variable frequency drive, these impellers provide slow sheer for mixing, high sheer for dispersion and anything in between. An anchor-stirrer, a U-shaped device, tracks the walls and bottom of the tank to prevent material from adhering to the surfaces.

The tanks can be jacketed and feature a stainless-steel wall and another carbon steel or stainless wall. Jackets are available for applications that are needed when heating or cooling are necessary. For example, material that moves very quickly can generate heat and friction that require cooling. Explosion-proof models are also available.

“We can offer a wide variety of options in terms of mixing tanks,” said Brian Li, Union Process Sales Manager. “These tanks are an important part of our processing solutions that perform effectively and dependably.”

Since 1946, Union Process has provided custom grinding and dispersion solutions for a wide variety of applications for customers all over the world.

Contact us for more information.

Company Contact

Union Process Inc.

Brian Li

bli@unionprocess.com

330.929.3333

The post Union Process Engineered Products Play Key Role in Overcoming Supply Chain Interruptions first appeared on Union Process.

]]>The post Union Process Announces Combination Lab Attritor first appeared on Union Process.

]]>

Akron, Ohio, April 30, 2021 — Union Process has developed a new combination Attritor mill that brings greater levels of speed and efficiency to the media grinding process for many of its customers all over the world.

The new Attritor combines the benefits of the HD and HDDM Attritors into one versatile unit. In the past, a changeover required releasing a belt guard, moving the belt to an alternate set of pulleys, replacing the guard and changing the coupling, shaft, and cover. The HD/HDDM combination Attritor eliminates this cumbersome process and provides the benefit of two mills in one. Both larger grinding media and micron particle size targets can be achieved with a simple changeover.

“This innovative, dual-mode mill provides a large range of size reduction capabilities for a wide variety of research and development applications–from three millimeters all the way down to the nanometer range,” said Brian Li, Sales Manager. “We’re always striving to bring new ideas to our customers, and this combination Attritor underscores that ongoing commitment.”

Since 1946, Union Process has provided custom grinding and dispersion solutions for a wide variety of applications for customers all over the world.

Contact us for more information.

The post Union Process Announces Combination Lab Attritor first appeared on Union Process.

]]>The post Union Process Develops Attritor for Inks and Coatings Supplier first appeared on Union Process.

]]>

Akron, Ohio…Union Process, Inc. has produced and delivered a “Q” series circulation Attritor to a major coatings and colorants technologies supplier in the U.S.

The UP Q-25 Circulation Attritor is fitted with a 27.5-gallon grinding tank capacity, a 250-gallon circulation tank, 25-gallon media volume, and a 20 HP explosion-proof motor with variable speed drive for precise speed control. The unit also features an alumina-lined grinding chamber, ceramic agitator arms, and an advanced control system that simultaneously monitors and regulates temperatures, flow rates, batch times, and other process critical functions.

“This model is widely recognized for its robust design and rugged build, in addition to is proven technology,” said Chuck Major, UP Sales Manager. “Because so many of these Q-25 units are in use, they’re also very easy to service, maintain, and upgrade.”

“The key advantages of circulation grinding include a high circulating or pumping rate—the entire contents of the holding tank are passed through the mill up to eight times per hour, resulting in a faster grind and narrower particle size distribution,” Major added. “Unlike a continuous machine where the slurry makes a single pass, the material makes many passes through the grinding chamber until the precise desired particle size is obtained.”Union Process, known globally as a manufacturer of particle size reduction and dispersing equipment, has been developing and building custom Attritors for customers with a wide variety of applications all over the world since 1946.

Contact us for more information.

The post Union Process Develops Attritor for Inks and Coatings Supplier first appeared on Union Process.

]]>The post Union Process Announces Launch of New Website first appeared on Union Process.

]]>

Akron, Ohio, March 3, 2021— Union Process, the world’s leading Attritor and grinding mill manufacturer, is pleased to announce the launch of its newly designed website. The new website features a modern, streamlined design, improved functionality, and more readily accessible information.

This dynamic site provides easy access to information regarding UP’s wide array of solutions for grinding and particle size reduction needs, including Attrition Mills, Horizontal Bead Mills, Grinding Media and more. A robust search function allows the user to find a very specific product or service quickly and easily. This feature was important because of the depth and complexity of the site and technical nature of the products offered.

“We were tasked with taking a great deal of complex information and making it manageable and approachable,” said Brian Li, Sales Manager. “Whether you know exactly what you’re looking for or need guidance in choosing the right mill or grinding media, the new site makes it easier.”The mobile-friendly site is now organized by U.S. states as well as countries abroad to better service its domestic and international clientele. It was also designed and built to WCAG 2.1 guidelines to better support accessibility for users with visual and motor skill limitations.

Since 1946, Union Process has provided custom grinding and dispersion solutions for a wide variety of applications for customers all over the world.

Contact us for more information.

The post Union Process Announces Launch of New Website first appeared on Union Process.

]]>